Complete solution for mixed chains

SCB | SMART CHAIN BENDING

Why bend chains?

To manufacture a chain, cut-to-length metal bars are bent into chain links in a bending machine. Due to the forces that occur, these rods are heated from a diameter of approx. 20mm before bending. Especially in mining chains every second chain link has a different geometry. When manufacturing these chains, pre-forged links must therefore also be bent into the chain. In order to meet these different requirements, we at ThermProTEC have developed a modular chain bending system in which all variants from pin and forged link feeding to palletizing of the final chain can be illustrated.

The essential components of such a system are the pin and individual link feed, the heating and aligning unit, the actual bending machine and the subsequent chain palletizing.

Module of the chain bending unit (SCB)

Pin and forged link feeder

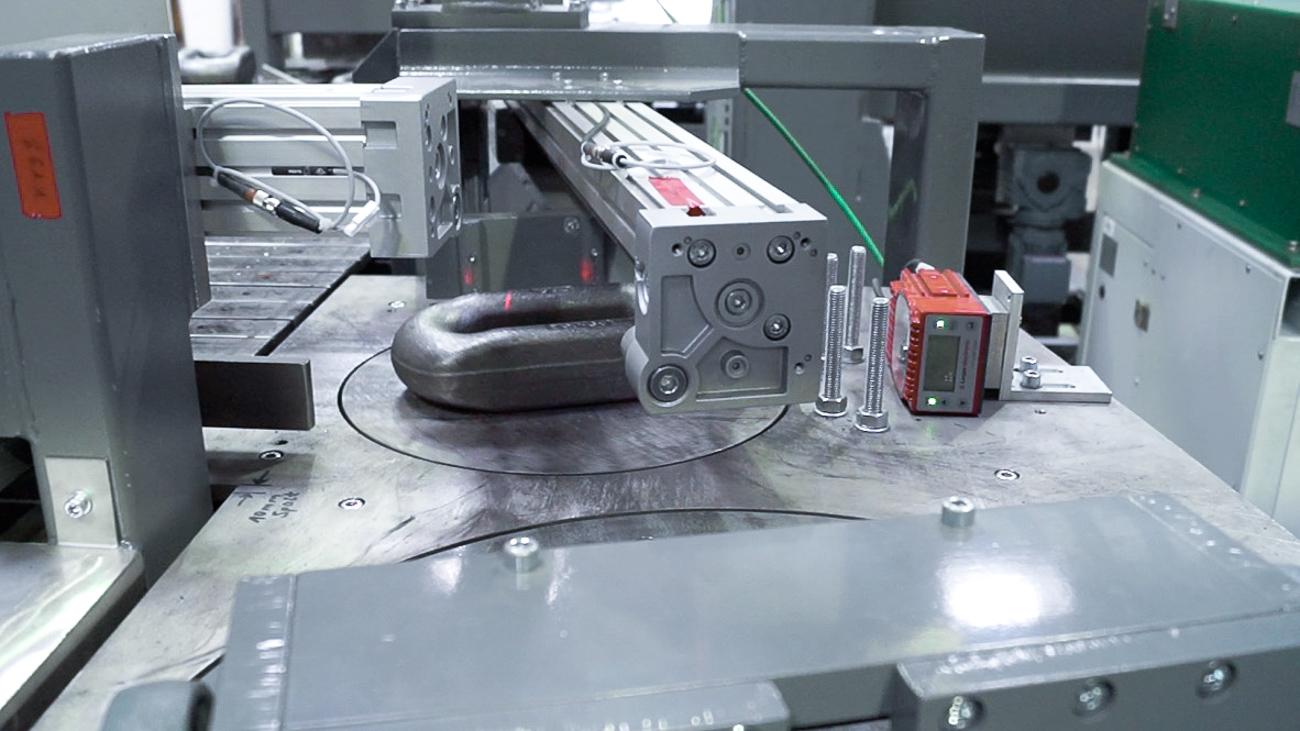

After application, round pins, forged pins and forged chain links must be automatically fed into the process. Containers are typically metal boxes from which the material is removed. In order to do justice to this application, we have developed a variable loading system with which the semi-finished products are removed by a magnetic loading portal and deposited on feeding belts. In the simplest version these are only straight pins with a box. In the largest expansion stage, round pins and forged pins or forged links can be removed from two boxes. The forged pins are fed to the heating unit by a step conveyor. The forging elements are oriented, monitored by camera systems, then aligned and fed to the bending machine.

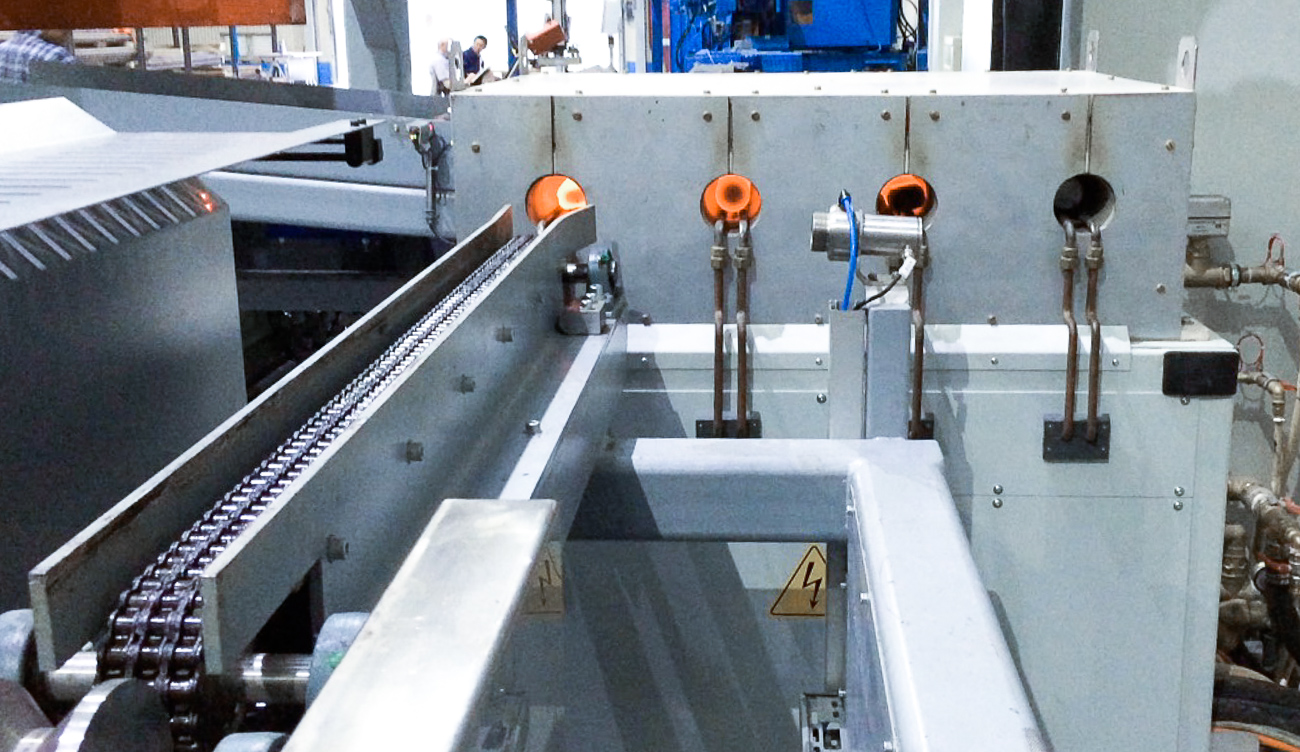

Heating unit

In hot bending the pins are heated to a temperature of approx. 800 °C. The homogeneity of the heating is decisive for the quality of the bending process. The heating takes place inductively in a three- or four-hole furnace. This oscillating system allows a sufficiently long heating time to ensure the heating of the pins. An integrated ejector unit then feeds the pins to the feed unit of the bending machine. Forged pins are additionally aligned in this unit. The induction units have a heating capacity of 200 and 300 kW respectively.

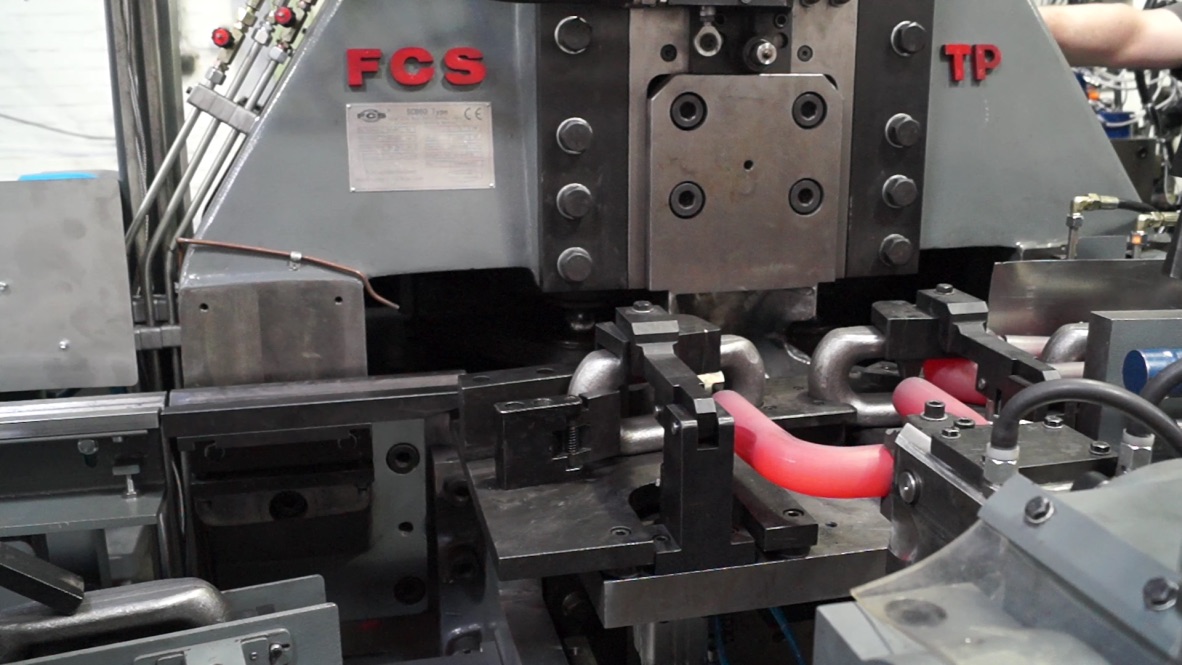

Bending machines

The bending machines differ both in the chain size (required bending force) and in the type of chain to be produced. The simplest version, Basic, allows the continuous production of round chains. The largest expansion stage enables the production of flat link chains from forged links. Individual links can also be produced with all machines and continuously removed from the line with a processing belt.

palletizing unit

chains are sorted into boxes after bending via a palletizing system. The chain is fed here with clamping wheels, with controlled depositing in strands. Depending on the safety requirements, the system is secured with a safety fence.

You are interested, have questions or suggestions?

Our team is at your disposal. We look forward to your message!

Zunftstr. 20 | 77694 Kehl-Marlen | DE

Related products:

Useful links

Contact