Induction hardening machines for shafts

HECTOR | HORIZONTAL HARDENING MACHINE

Why this system concept for shafts?

Our Hector series of hardening machines describes a series of horizontal hardening machines which, like the Vector series, combine the hardening process and the tempering process. The main area of application is the quenching and tempering of wave-like components where asymmetrical hardening processes are required.

System design

Handling concept

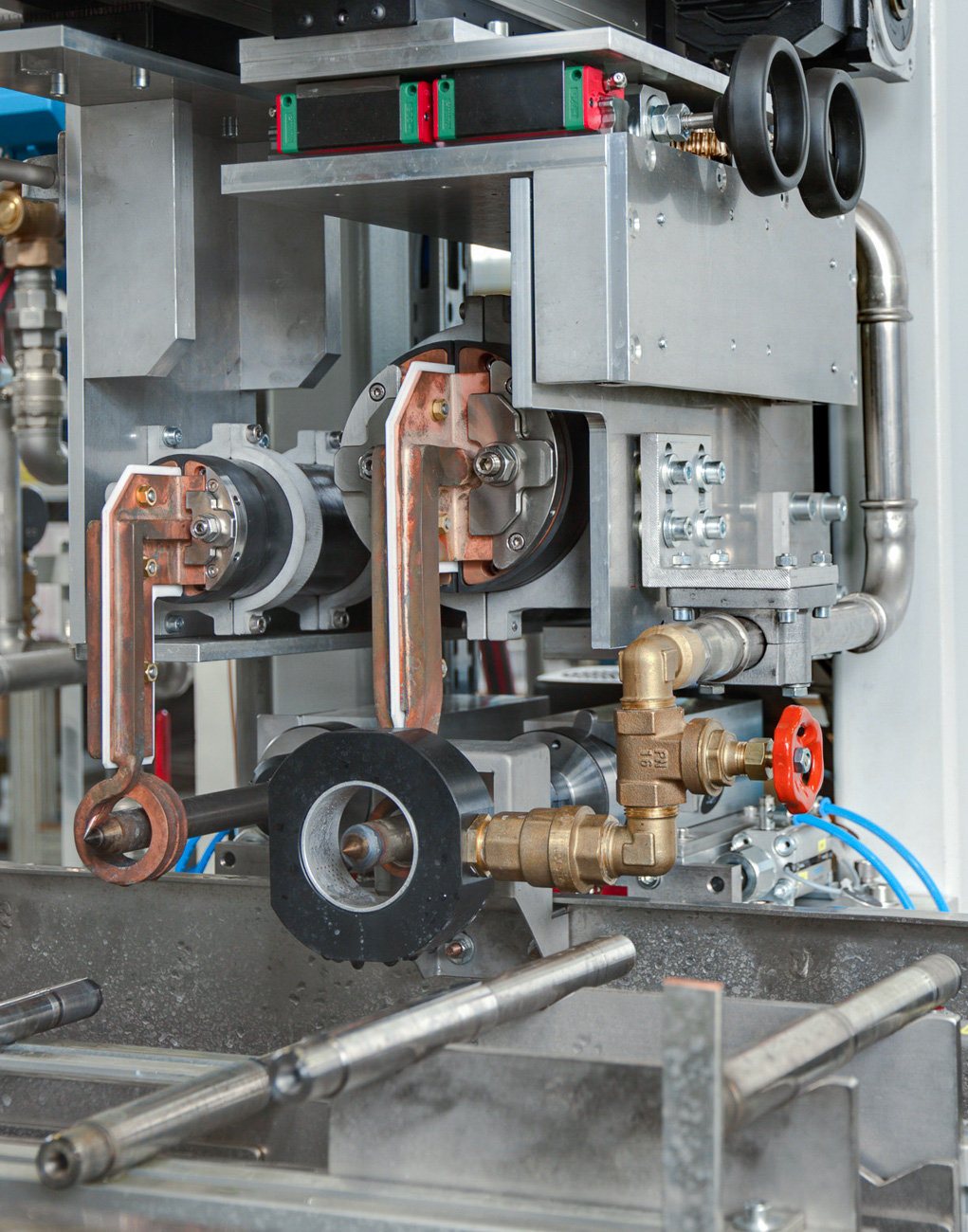

The central element in the conveying of the components is a walking beam conveyor with which the components are continuously conveyed through the system. The heating technology used is inductive heating, whereby hardening is carried out according to the feed hardening principle. After the clocking with the walking beam, the inductor with circular shower is pneumatically clamped over tips. The rotary drive is integrated into the tip system. With the non-driven tip, the rotation is monitored by a sensor, which ensures safe positioning.

Inductive heating concept

With feed hardening, both the heating power and the feed speed can be individually varied. This allows the desired hardness profile to be set. Tempering takes place in the following cycle using the same rotation principle. The positioning of the coil is controlled and adjusted by a servo drive. The quench polymer is collected below the walking beam conveyor and fed to the tank via a fleece filter system. Temperature, polymer concentration and flow rate are continuously recorded and recorded in a database system. An electrostatic filter is integrated for extracting the vapours. The standard system is equipped with an induction generator with two separately controllable oscillating circuits. The total power of the generator is 140 kW (120 kW hardening / 20 kW starting) in the frequency range 6-10 kHz. Depending on the application, other generator outputs can also be used here. Both the inductors and the ring shower are easy to change via a quick-change system and can be adapted to the component geometry. The construction of the entire plant is integrated into a steel construction and enables fast commissioning on site. An additional special feature of this system is that a very homogeneous heating of the components is achieved by means of an oscillating process. By means of adapted inductors, strongly varying diameters can be imaged in the component, whereby e.g. shaft journals can be hardened. This system has proven itself many times in the automotive industry.

You are interested, have questions or suggestions?

Our team is at your disposal. We look forward to your message!

Zunftstr. 20 | 77694 Kehl-Marlen | DE

Related products:

Useful links

Contact